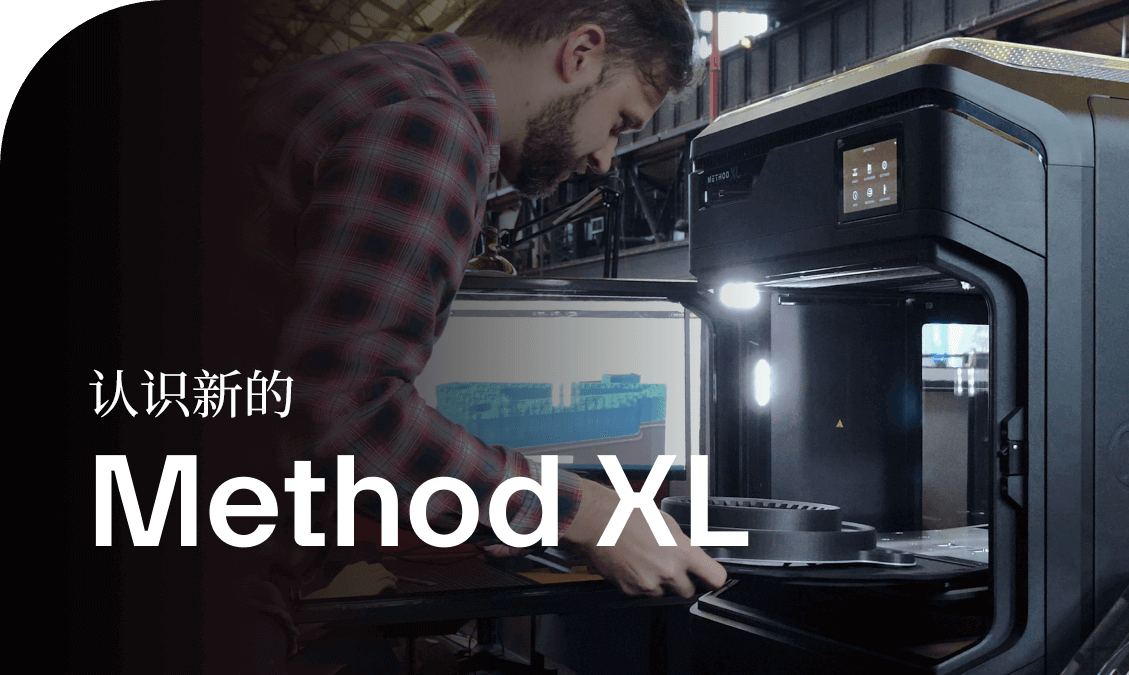

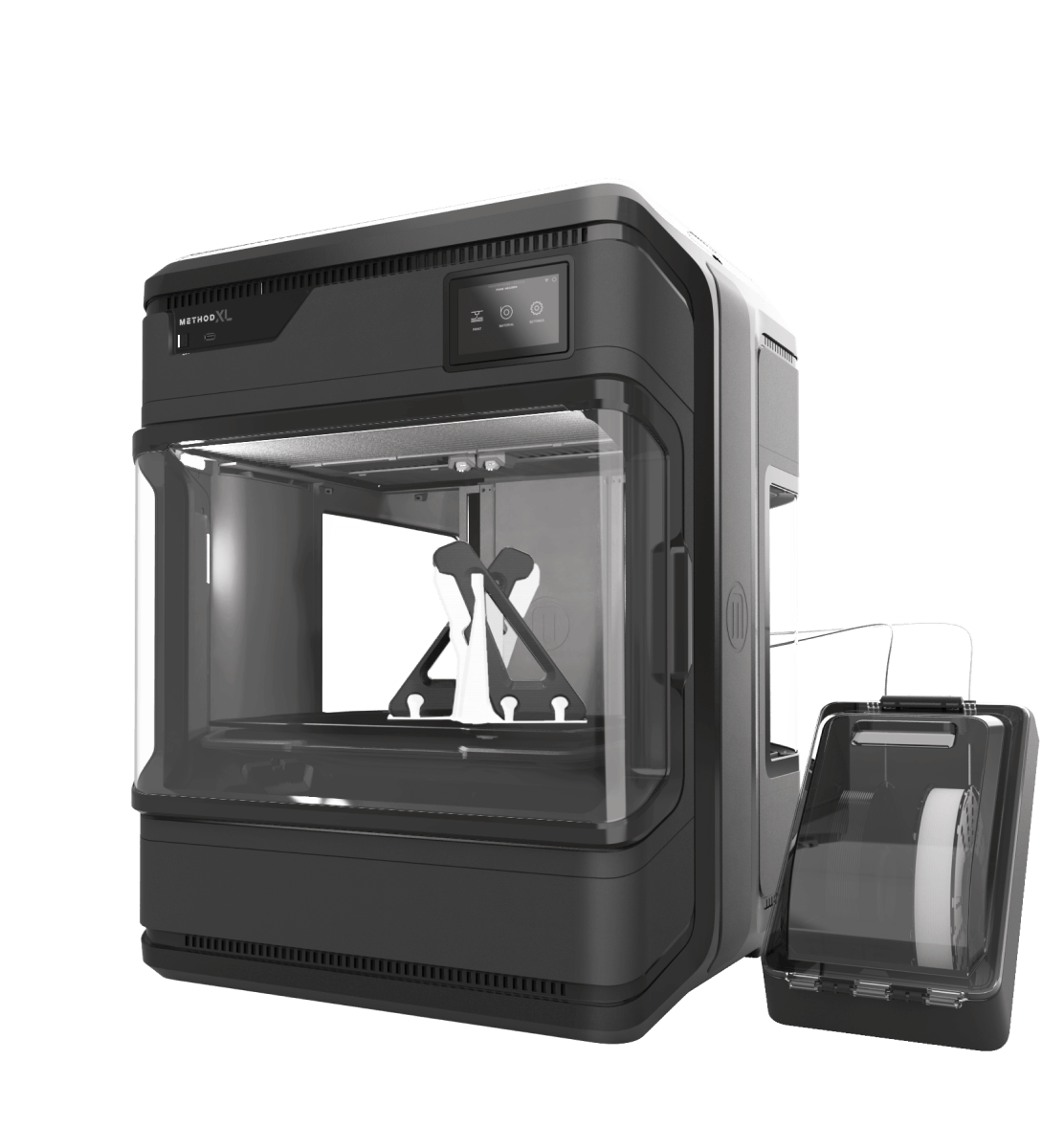

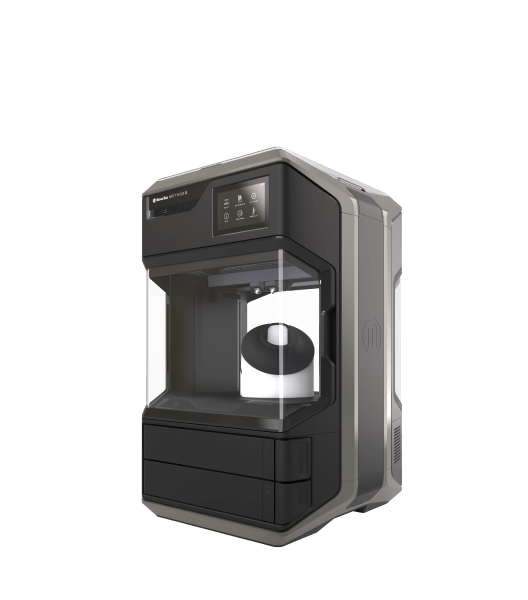

不妥協!

超大構建體(tǐ)積

Method XL擁有(yǒu)所有(yǒu)UltiMaker打印機中(zhōng)最大的構建體(tǐ)積,這使其成為(wèi)大型項目的終極 3D 打印解決方案。

使用(yòng)工(gōng)業級材料和卓越的尺寸精(jīng)度進行打印,無需犧牲零件的尺寸。

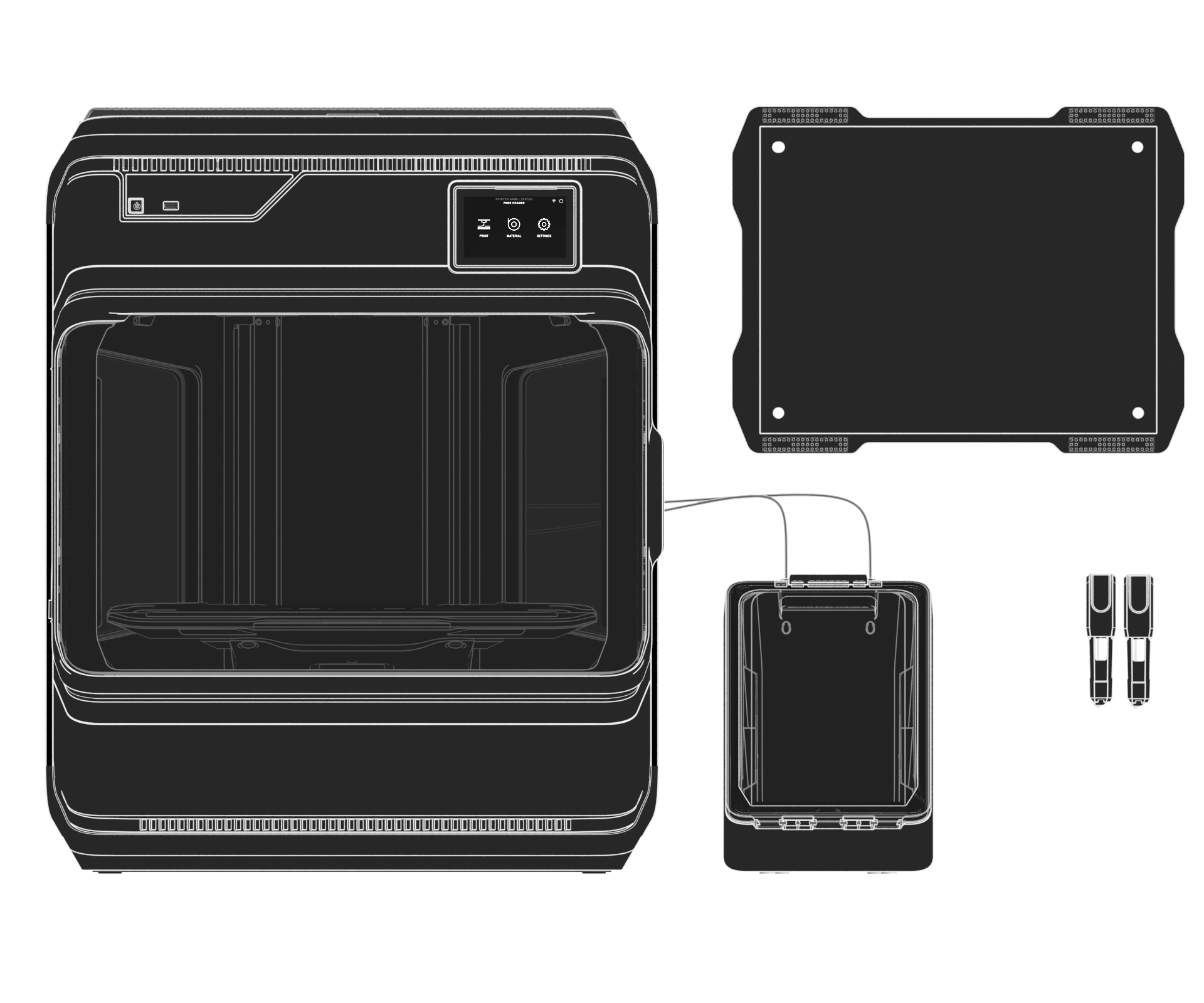

雙擠出成型體(tǐ)積 (XYZ)

x = 305 mm

12 inches

y = 305 mm

12 inches

z = 320 mm

12.6 inches